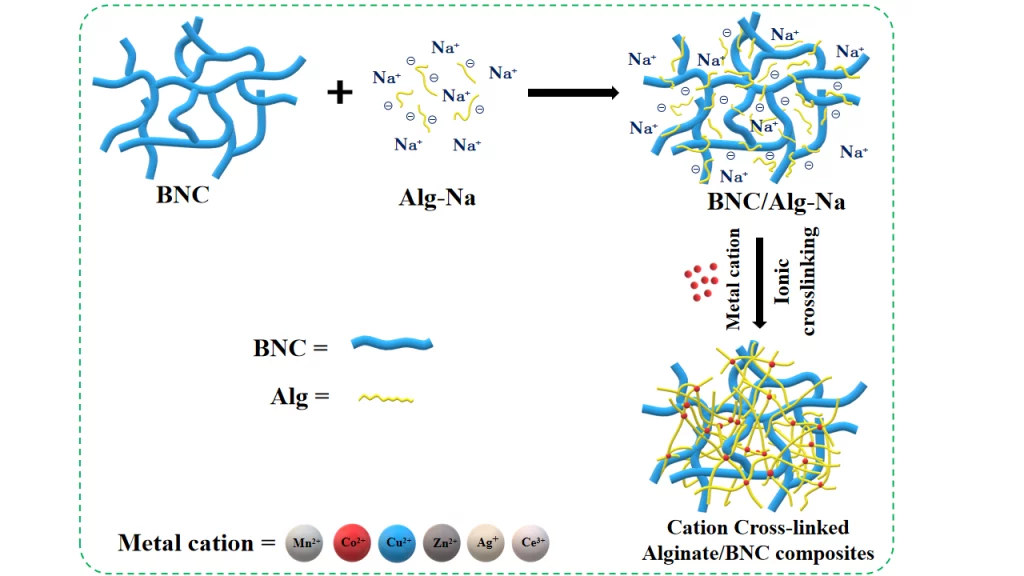

Alginate (Alg) and bacterial nanocellulose (BNC) have exhibited great potential in biomedical applications, especially wound dressing. Non-toxicity and a moisture-maintaining nature are common features making them favorable for functional dressing fabrication. BNC is a natural biopolymer that promotes major advances to the current and future biomedical materials, especially in a flat or tubular membrane form with excellent mechanical strength at hydrated state. The main drawback limiting wide applications of both BNC and Alg is the lack of antibacterial activity, furthermore, the inherent poor mechanical property of Alg leads to the requirement of a secondary dressing in clinical treatment. To fabricate composite dressings with antibacterial activity and better mechanical properties, sodium alginate was efficiently incorporated into the BNC matrix using a time-saving vacuum suction method followed by cross-linking through immersion in separate solutions of six cations (manganese, cobalt, copper, zinc, silver, and cerium). The results showed the fabricated composites had not only pH-responsive antibacterial activities but also improved mechanical properties, which are capable of acting as smart dressings. All composites showed non-toxicity toward fibroblast cells. Rat model evaluation showed the skin wounds covered by the dressings healed faster than by BNC.

Bacterial nanocellulose-enhanced alginate double-network hydrogels cross-linked with six metal cations for antibacterial wound dressing.

Testing

Testing